본문

Development of a sprayable antimicrobial formulation using hydrophobic yeast for one-step deposition on plastic surfaces and prevention of bacterial cross-contamination of baby spinach

By prof. Hansol Doh

Department of Food Science & Biotechnology

PURE Research Profile

hdoh@ewha.ac.kr

Background

Surface-mediated microbial cross-contamination remains a critical food safety challenge in fresh produce handling environments, including processing lines, packaging materials, and contact surfaces. Although routine sanitation procedures reduce microbial loads, they do not provide persistent protection against recontamination. Existing antimicrobial coatings often rely on polymeric binders or surface modification steps that limit food-grade applicability, increase processing complexity, and reduce long-term durability under mechanical stress. Therefore, there is a clear need for a simple, food-compatible, and mechanically robust antimicrobial coating that can be readily applied to commonly used plastic surfaces.

Overview

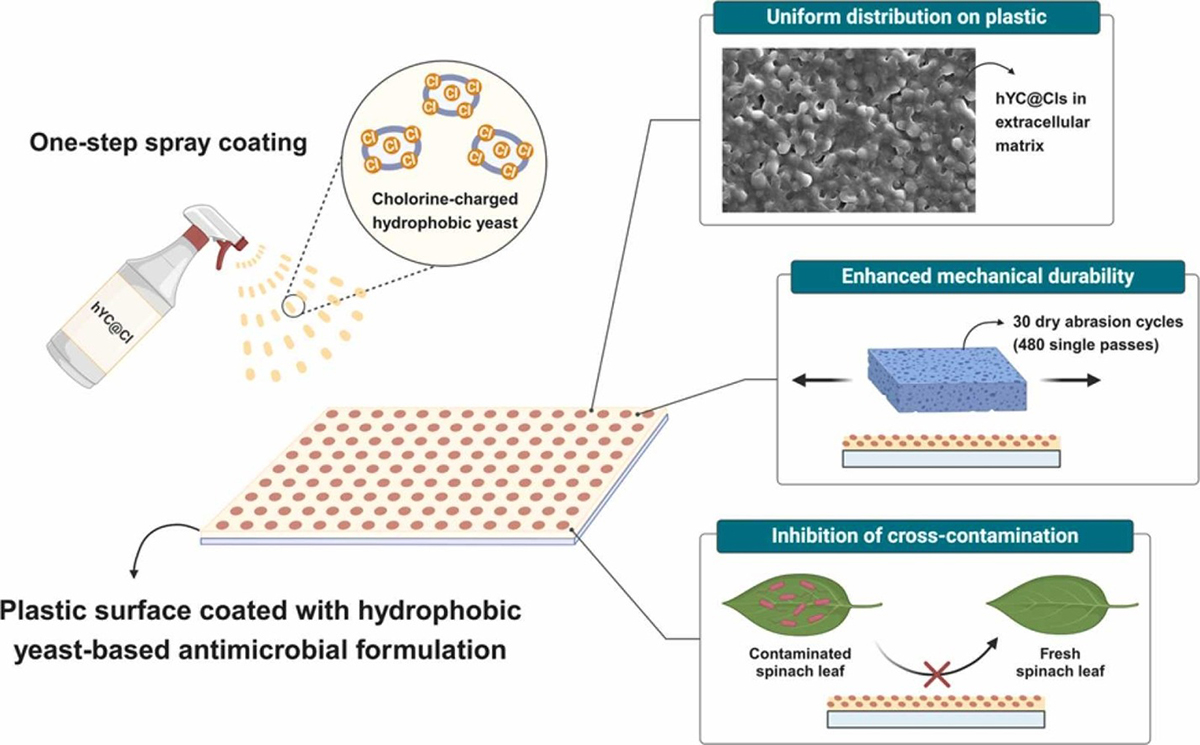

This study presents a one-step sprayable antimicrobial coating based on chlorine-charged hydrophobic yeast cells (hYC@Cl). The approach exploits the intrinsic hydrophobicity of selected Saccharomyces cerevisiae strains, enabling direct adhesion to polypropylene surfaces without the use of external binders. Chlorine is stably immobilized on yeast cell wall amine groups through N-halamine formation, allowing the yeast cells to function simultaneously as an antimicrobial carrier and a surface-binding agent. The formulation can be sprayed directly onto plastic surfaces, producing a uniform coating layer with minimal processing requirements.

Figure 1. chematic illustration of a one-step spray coating strategy using chlorine-charged hydrophobic yeast cells (hYC@Cl) for uniform deposition on plastic food-contact surfaces, enhanced abrasion resistance, and inhibition of produce cross-contamination.

Results

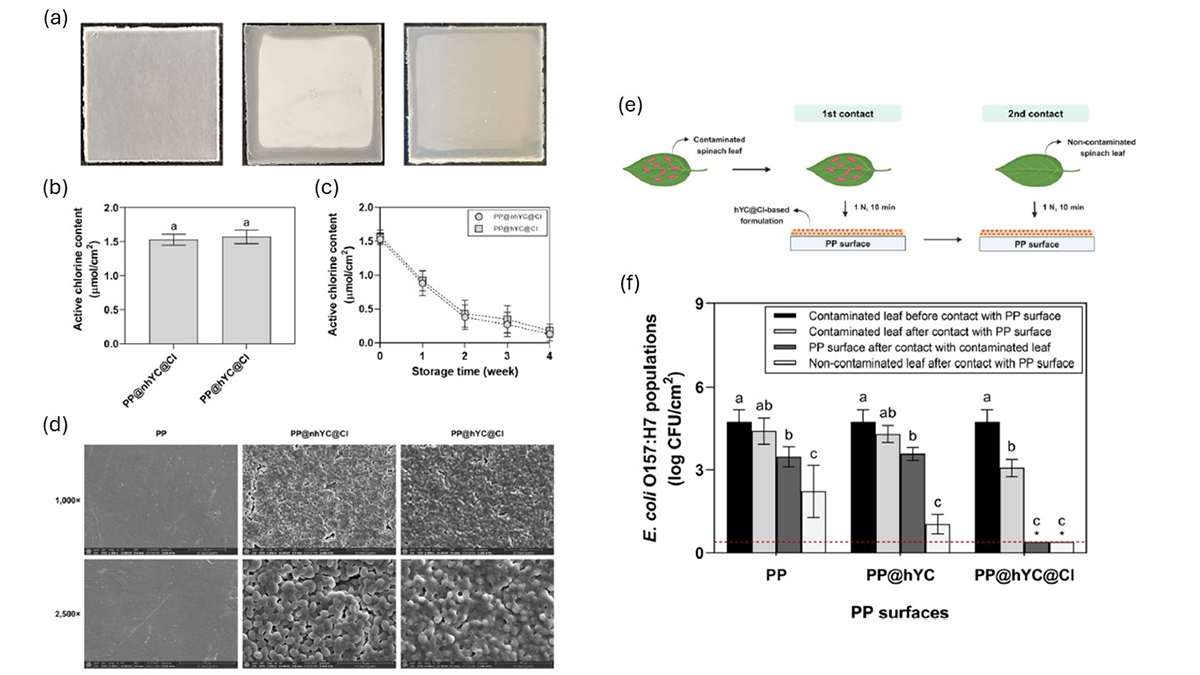

Surface characterization confirmed that hYC@Cl particles were evenly distributed across polypropylene surfaces, forming a cohesive layer that included extracellular matrix-like structures. The coated surfaces retained measurable active chlorine during storage, indicating chemical stability of the antimicrobial functionality. Antimicrobial assays demonstrated rapid and strong inactivation of both Escherichia coli O157:H7 and Listeria innocua, with reductions exceeding 5 log units within minutes of contact.

Mechanical durability testing revealed that hYC@Cl-coated surfaces exhibited significantly higher resistance to dry abrasion compared to coatings prepared with less hydrophobic yeast cells. Even after 30 abrasion cycles, corresponding to extensive mechanical stress, hYC@Cl coatings retained sufficient active chlorine to maintain antimicrobial activity below detection limits. In simulated leaf–surface–leaf cross-contamination experiments using baby spinach,

hYC@Cl-coated polypropylene surfaces completely prevented bacterial transfer to fresh leaves and exhibited self-cleaning behavior after contact with contaminated produce. These findings highlight the role of yeast surface hydrophobicity in maintaining coating integrity and antimicrobial performance under realistic handling conditions.

Figure 2. Optical images of polypropylene (PP) surfaces before and after coating, (a); active chlorine content of yeast-coated PP surfaces, (b); Storage stability of active chlorine on coated PP, (c); SEM images showing uniform distribution and extracellular matrix formation of hYC@Cl on PP at different magnifications, (d); simulated leaf–surface–leaf cross-contamination test demonstrating effective inhibition of E. coli O157:H7 transfer, (e–f).

Future Direction

Future work should focus on identifying the specific yeast cell wall components responsible for enhanced hydrophobic adhesion and mechanical stability, potentially through proteomic analysis. Optimization of formulation stability through drying or rehydration strategies will be important for large-scale deployment. In addition, long-term performance under repeated wet cleaning and sanitation cycles should be evaluated on industrial processing equipment. Collectively, these efforts will support the translation of this bio-based, binder-free antimicrobial coating platform into practical applications for improving microbial safety in fresh produce handling environments.

* Related Article

Yoonbin Kim, Hansol Doh, Nitin Nitin, Development of a sprayable antimicrobial formulation using hydrophobic yeast for one-step deposition on plastic surfaces and prevention of bacterial cross-contamination of baby spinach, Postharvest Biology and Technology, 228, 2025.