본문

Integrated Scheduling of Real-time and Interactive Tasks for Configurable Industrial Systems

By Prof. Hyokyung Bahn

Department of Computer Science & Engineering

PURE Research Profile

bahn@ewha.ac.kr

With the recent advances in IoT (Internet of Things) and CPS (Cyber Physical Systems) technologies, smart industrial systems support configurable processes consisting of human interactions as well as hard real-time functions. For example, an autonomous driving system can operate more efficiently if it allows additional interactions with drivers rather than operates in a fully autonomous mode. Similarly, in smart factory, production lines need to be smart and flexible, which requires the manufacturing processes configurable by supporting human interactions as well as hard real-time functions. Thus, future industrial systems essentially have heterogeneous workloads consisting of irregularly arriving interactive tasks and traditional hard real-time tasks. In this situation, if the operating system manages a certain portion of the resources separately for real-time and interactive tasks, the utilization of the resources is greatly degraded. Thus, resource management in smart industrial systems should consider not only real-time or interactive tasks themselves, but also the characteristics of their mixture.

We propose a new task scheduling policy, called DGIS (Dynamic Genetic based Integrated Scheduling), which schedules the task set consisting of heterogeneous tasks. Our policy aims at minimizing the energy consumption of industrial systems without missing the deadlines of real-time tasks and also ensuring an acceptable waiting time for interactive tasks. As such type of systems are usually operated based on limited power facilities, reducing energy consumptions is important. We make use of dynamic voltage scaling (DVS) and hybrid memory (HM) techniques for reducing the energy consumption of industrial systems. DVS offers flexibilities between the power-saving and the computational speed by adjusting the supply voltage of a processor. HM adopts low-power memory media such as NVM (non-volatile memory) along with DRAM and reduces memory power consumptions by placing tasks on NVM instead of DRAM. Although DVS and HM reduce the power consumption, they increase the execution time of tasks, possibly resulting in the deadline misses of real-time tasks. This is because DVS slows down the computational speed of processors and tasks in NVM require more time to access than those in DRAM. Thus, we need to decide the power-saving configurations of each task not to violate the deadline constraints.

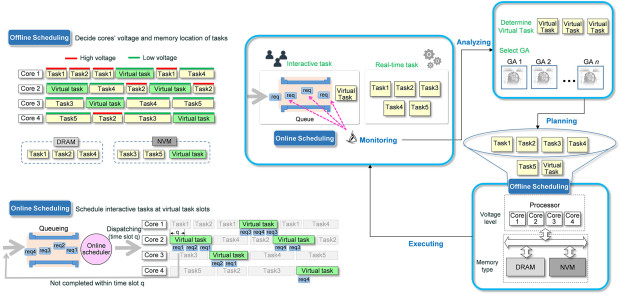

Meanwhile, there is a fundamental difference between the management philosophy of real-time and interactive tasks. Since hard real-time tasks must keep their deadlines, offline scheduling is commonly performed based on the worst case execution time and the period of the task set. In contrast, interactive tasks do not have deadlines, and thus the system pursues the best-effort service for utilizing the given resources efficiently. As the characteristics of the tasks are different, it is not an easy matter to schedule them all at once. To cope with this situation, we use the notion of “virtual real-time task” for sporadically arriving interactive tasks. Specifically, we monitor the load of interactive tasks periodically, and add the virtual real-time tasks for reserving the resources while offline scheduling. During this process, tight planning of given resources is performed by accurately evaluating the scaled worst-case execution time of real-time tasks and the load of interactive tasks, thereby reducing the energy consumption of the system significantly without performance penalties.

Our scheduling consists of two phases. First, offline scheduling is performed for hard real-time tasks (including virtual realtime tasks). It aims at finding the processor’s voltage level and the memory location of each task that lead to the minimized energy consumption. This is a typical combinatorial optimization problem, and we use genetic algorithms (GAs). The system is then executed based on the resource states decided by this offline scheduling. Second, if interactive tasks actually arrive during the execution, they are allocated to the time slot of the virtual real-time tasks, and online scheduling is performed for the interactive tasks. Meanwhile, as the load of interactive tasks may change over time, our offline scheduling is periodically updated with the new virtual real-time tasks determined through the monitoring result of recent interactive tasks. This guarantees the acceptable waiting time for interactive tasks as well as minimizing the power consumption. Our simulations under a wide range of workload conditions show that the proposed policy saves the energy consumption of industrial systems significantly. Specifically, the energy-saving effect is 66.8% on average without deadline misses. It also provides the waiting time of less than 3 seconds for interactive tasks although the load of the interactive tasks is largely varied.

This research was published in IEEE Transactions on Industrial Informatics, which has the highest impact factor of 10.215 among all journals in the Industrial Engineering category of the most recent Journal Citation Reports. We also presented this research result in the work-already-published session of 2021 IEEE Real-Time System Symposium (RTSS), the No. 1 conference in real-time system field.

Fig. 1 An overview of our task scheduling.

* Related Article

S. Yoo, Y. Jo, and H. Bahn, “Integrated scheduling of real-time and interactive tasks for configurable industrial systems,” IEEE Transactions on Industrial

Informatics, vol. 18, no. 1, pp. 631-641, 2021.